Hot Forging Has The Answer To Everything.

These phases normally present the workpiece with generous bends and also huge fillets. The final shape is built in a "final" or "finisher" impact dental caries. If there is just a short run of components to be done, then it may be much more affordable for the die to do not have a last perception dental caries and instead equipment the final functions.

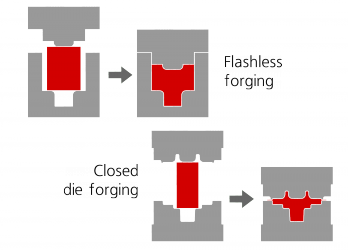

One variant of impression-die building is called "flashless building", or "real closed-die forging". In this kind of forging, the die dental caries are totally closed, which maintains the work surface from developing flash. The major benefit to this process is that less steel is shed to flash - Hot Forging. Flash can make up 20 to 45% of the starting product.

There are other variations of component formation that incorporate impression-die building. One method integrates casting a creating preform from liquid steel. The casting is removed after it has strengthened, but while still hot. It is then completed in a solitary tooth cavity die. Hot Forging. The flash is trimmed, then the component is appease set.

Closed-die forging has a high initial expense because of the development of passes away and needed style job to make functioning pass away dental caries. It has low persisting costs for each component, thus forgings become more economical with higher manufacturing quantity. This is among the significant factors closed-die forgings are usually utilized in the automotive and also device sectors.

Building dies are generally made of high-alloy or device steel. Dies should be influence- and wear-resistant, preserve toughness at high temperature levels, have the ability to endure cycles of fast heating & cooling. In order to generate a far better, a lot more affordable pass away the complying with criteria are maintained: The dies part along a solitary, flat aircraft whenever feasible.

The parting surface area is an airplane with the center of the building and not near a top or reduced edge. Sufficient draft is offered; usually at the very least 3 for aluminium as well as 5 to 7 for steel. Charitable fillets and also distances are utilized. Ribs are low as well as large. The different sections are balanced to avoid severe distinction in steel circulation.

Dimensional tolerances are not closer than required. Barrelling happens when, because of rubbing between the work piece and also the die or punch, the job item protrudes at its centre in such a means regarding look like a barrel. This results in the main component of the work item ahead in call with the sides of the die quicker than if there were no rubbing existing, developing a much better rise in the stress needed for the strike to end up the building.

The dimensions throughout the parting airplane are impacted by the closure of the passes away, as well as are consequently depending on die wear as well as the thickness of the last flash. Hot Forging. Dimensions that are completely consisted of within a solitary die section or half can be maintained at a considerably higher level of accuracy.

A lubricant is made use of when creating to reduce rubbing as well as wear. It is likewise utilized as a thermal barrier to limit warm transfer from the workpiece to the die.

评论

发表评论