The Ultimate Revelation Of Cnc Milling.

In zig milling, the device relocates just in one instructions. The device needs to be raised and also pulled back after each cut, as a result of which machining time boosts. Nevertheless, in situation of zig milling surface area quality is much better. In this technique, device movement is multi-directional. One example of non-linear device path is contour-parallel tool course (cnc milling).

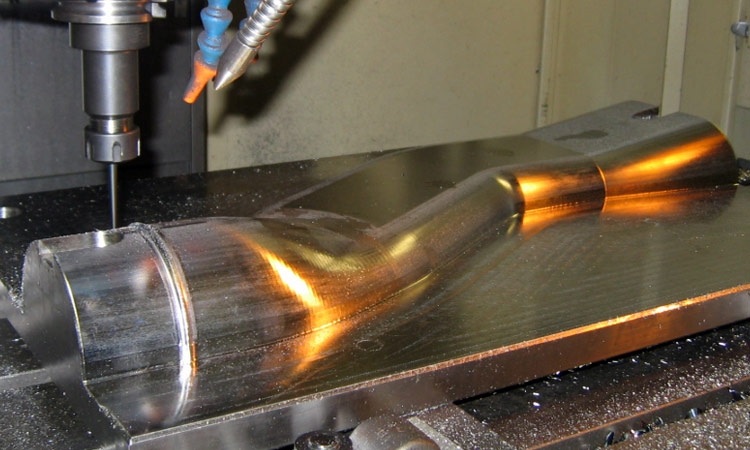

In this case the cutter is always touching the work material. For this reason the still time invested ready and pulling back the tool is avoided. For massive material elimination, contour-parallel device course is extensively utilized due to the fact that it can be constantly utilized with up-cut or down-cut approach during the entire process - cnc milling.

They are: Pair-wise junction approach: In pair-wise intersection approach, the limit of the pocket is brought inwards symphonious, The countered sectors will certainly intersect at concave corners. To get the called for shape, these junctions are to be cut off. On the various other hand, in case of convex edge, the countered sectors are prolonged as well as consequently linked to make the shape.

offsetting, cutting and also prolonging are repetitively done to cover the entire machining volume with sufficient layer of profiles. Voronoi layout technique: In voronoi representation method, the pocket boundary is segmented as well as voronoi diagram is created for the entire pocket boundary. These voronoi representations are made use of for generating the tool path for machining.

Moreover, it prevents topological issues connected with conventional offsetting algorithms (cnc milling). In this method, the device follows a progressively developing spiral course. The spiral begins at the center of the pocket to be machined and the tool slowly relocates in the direction of the pocket boundary. The instructions of the device path adjustments progressively as well as local velocity and slowdown of the device are decreased.

Contour-parallel tool course Milled equipment teeth on a Terry design wood activity clock. Milling devices advanced from the practice of rotating filingthat is, running a circular cutter with documents- like teeth in the headstock of a turret - cnc milling. Rotary declaring as well as, later, true milling were developed to reduce effort and time invested hand-filing.

However, the wide details are understood, as summarized listed below. From a history-of-technology perspective, it is clear that the naming of this brand-new kind of machining with the term "milling" was an expansion from that word's earlier senses of processing materials by abrading them in some method (cutting, grinding, squashing, etc.).

评论

发表评论