Simple Guidance For You In Cold Forging.

A vital, and also enhancing factor, is the addition of automation and also robotics, which is quickly changing the face of the sector. A building specialist can aim you in the appropriate instructions to discover the procedure that best fits your requirements. Cold building equipment and also devices come in three ranges hydraulic, pneumatic, and mechanical.

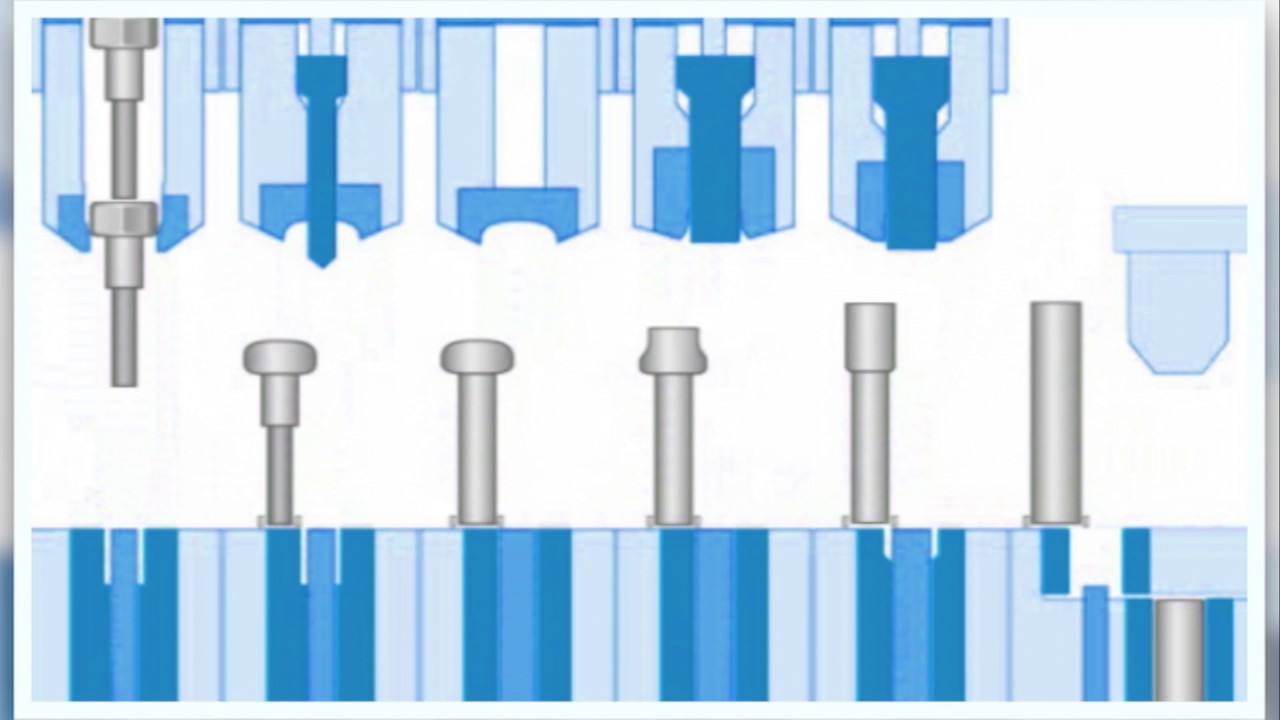

Technology and automation are typical as you can see aware below, which is a servo cold forging press from Wonder Equipment. Part layout renderings are produced using design software such as CAD. Force - Cold building processes depend upon a tremendous amount of pressure. The devices attached with it needs to can soaking up that force as well as dissipating it.

Stamina with time - No matter the approach of cold forging, each needs effective repeated pressure. For a device to last, it has to be able to withstand that pressure. Multiple procedures - Modern chilly building or developing devices, called headers, full one to several operations throughout one procedure. This is needed given that there is a limited quantity of flawing that can be performed with one stroke.

It can generate a vast variety of impacts from a variety of dies. It runs utilizing the engineering principles of hydraulics where an incompressible liquid is contained in a cyndrical tube. When the liquid is pressed by a piston, a shaft, with the die attached, is driven down onto the work surface.

It can be utilized for flashless dies and lengthy rod forgings. The setup of the screw press enables it to be utilized for solitary port passes away that consist of flexing as well as final forgings. cold forging. An electrical motor supplies the power to transform the screw that presses the die onto the workpiece. Screw Press The C frame style appropriates for developing, punching, flexing, as well as multi-pressing operations.

They can accept pass away heights of 435 to 600 mm as well as can be made use of to generate small parts (cold forging). C Frame Forming Press( from Beckwood Company) The pneumatic powered press can cover the complete range of die pushing features. They come with a pneumatically powered operated friction clutch and also brake. The power for the press is created by an air compressor that compels the forging hammer down onto the work surface by atmospheric pressure in a cylinder with a piston.

评论

发表评论